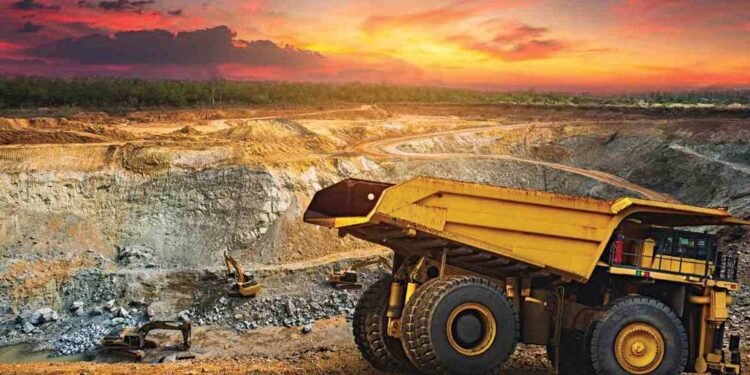

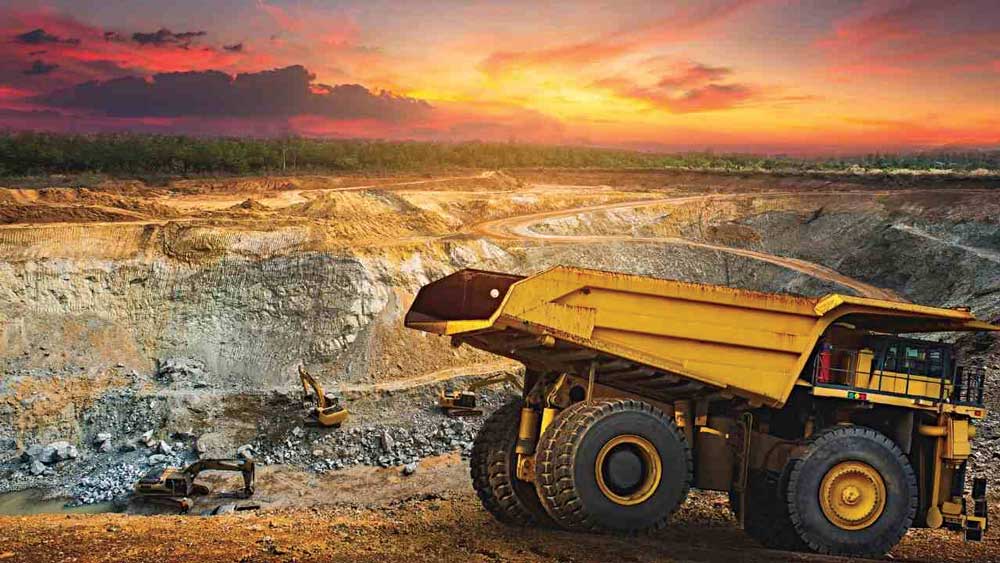

When it comes to the mining industry, the demand for durable and reliable materials is paramount. One such material that plays a crucial role in meeting these requirements is steel. It is an indispensable component in the mining sector. It’s used in everything from structures, such as a mining building, to most mining tools. It has exceptional strength, versatility, and resistance to wear and tear. Here’s a look at the key steel features that cater to the mining industry’s needs.

High Tensile Strength:

Steel used in the mining industry is known for its exceptional tensile strength. Tensile strength refers to a material’s ability to withstand pulling forces without deforming or breaking. Heavy machinery and equipment exert significant forces in mining operations, and steel’s high tensile strength ensures it can endure these rigorous conditions without compromising its structural integrity.

Abrasion Resistance:

Mining operations often involve abrasive materials such as rocks, minerals, and ores. These abrasive elements can cause severe wear and tear on equipment and machinery components. The steel used in the mining industry is designed to be highly resistant to abrasion, ensuring prolonged durability and reducing maintenance costs.

Corrosion Resistance:

Another critical feature of steel used in the mining industry is its corrosion resistance. Mining activities often occur in harsh environments where exposure to moisture, chemicals, and other corrosive agents is common. Corrosion can weaken equipment and structures, leading to safety hazards and increased maintenance expenses. Steel with excellent corrosion resistance helps protect against these detrimental effects, ensuring longevity and reliability.

Heat Resistance:

Mining operations can generate high temperatures due to various factors, such as friction or heat from adjacent processes. The steel used in the mining industry is engineered to withstand elevated temperatures without losing its strength or integrity. This heat resistance property ensures that steel components endure extreme conditions, reducing the risk of failures and operational disruptions.

Weldability:

It refers to the ease with which two steel pieces can be joined together using welding techniques. In mining, welding is commonly used to fabricate and repair equipment and structures. Steel’s excellent weldability enables efficient and reliable welding processes, ensuring the integrity and strength of the final product.

Impact Resistance:

Mining operations often involve heavy impacts and shocks, particularly rock drilling and blasting. Steel’s high impact resistance is crucial in such scenarios, as it can withstand sudden forces without fracturing or deforming. This property ensures the safety of personnel and the longevity of equipment, making steel an ideal choice for mining applications.

Versatility:

Steel’s versatility is another significant advantage in the mining industry. It can be easily shaped and formed into various components and structures to suit specific needs. Whether it’s conveyor belts, structural supports, a mining building, or mining tools, steel can be customized to meet the diverse requirements of mining operations effectively.

In conclusion, steel has a range of essential features that cater to the mining industry’s needs. Its high tensile strength, abrasion resistance, corrosion resistance, heat resistance, weldability, impact resistance, and versatility make it an ideal material for mining applications.

By incorporating steel into their operations, mining companies can benefit from enhanced durability, reduced maintenance costs, and increased operational efficiency. Steel plays a vital role in the mining industry, supporting its growth and ensuring the reliability and safety of mining operations worldwide.