Injection molding is a cost-effective process to manufacture plastic products. But this process is only cost-effective when you are manufacturing a large number of products. But how do you calculate the number? We will find the answer in this article.

Why does the cost of Injection Molding depend on the unit?

Injection molding or Custom injection molding is cost-effective only when you are producing a large number of products.

The reason behind this is the initial cost of injection molding. Injection molding has a higher tooling cost. Therefore, if you order one or two pieces, that will be hugely expensive.

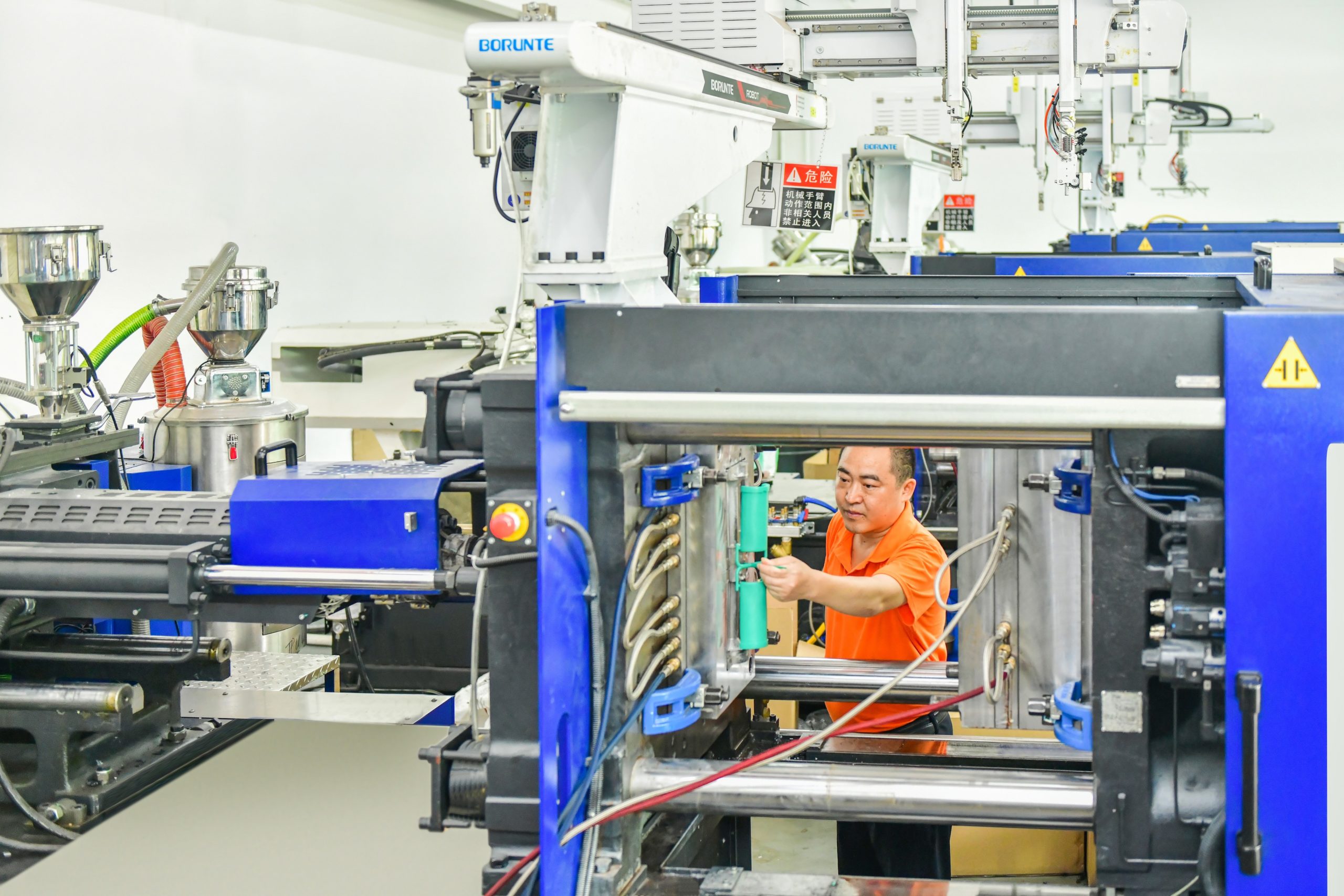

Figure 1 – Injection Molding

Let us clear it with an example. Suppose you are a toy guitar manufacturer. If you use injection molding to manufacture your toy guitar, the stainless steel mold of a guitar will cost roughly USD 6000, and the plastic toy guitar you are going to produce will cost USD 0.6.

So, if you order one unit, that will cost you USD 6000.6. But if you order ten units, the cost will be USD 6006.0 only. Can you see the difference in price between the first and the last nine units? And what if you order 1,000 units? It will cost only USD 7000. The higher you produce, the lesser you pay – that is the simple rule of injection molding.

But how would you define the number? Should you choose injection molding or 3D printing? How would you choose? How many numbers are the “cost-effective number for injection molding” for you?

Injection Molding Or 3D Printing What to Choose?

3D printing and Injection molding both are effective options for plastic parts manufacturers or prototyping companies.

While Prototyping

Most manufacturers will prefer 3D printing for prototyping. But that should not be the case for all scenarios. Suppose your R&D team needs one or multiple prototypes just to take a look at the outcome of their design; 3d printing will be an ideal choice.

Figure 2 – 3D printing

But if you are manufacturing a product for a client and making the prototype for pitching purposes, you want to make everything perfect. In that case, Injection molding will be a better choice. Even though it is expensive, if you can satisfy your client and they order a large quantity, the initial cost will transfer into a cost-effective manufacturing process for you.

The Economic Difference

3D printing is a one-time process. It needs no tooling. You provide the design, and the machine will print you the product. As there is no tooling needed, it is a better option if you need less number of products.

Injection molding, on the other hand, comes at a higher initial cost. However, the cost reduces as you increase the number of products. So, we can say that injection molding is a dynamic process. Once you finish the tooling process, your cost reduces, and the production speed increases.

How Injection Molding makes the Large production Cost-Effective – The parts

The Mold

How does injection molding reduce your price for large production compared to 3D printing? Let’s take a hypothetical scenario to explain the topic. For example, you are a toy guitar manufacturer.

For this example purpose, we are considering the initial cost of steel mold is USD 6000 and Aluminum mold is 1500. Let’s consider the next each production will cost you 50 cents. For better demonstration, look at the below table:

| Steel Mold | Aluminum Mold | 3D Printing | ||||

| Units | Total cost | Per unit cost | Total cost | Per Unit cost | Total cost | Per Unit cost |

| 1 | 6000.5 | 6000.5 | 1500.5 | 1500.5 | 25 | 25 |

| 10 | 6005 | 605 | 1505.0 | 150.5 | 250 | 25 |

| 100 | 6050 | 60.5 | 1550 | 15.5 | 2500 | 25 |

| 1000 | 6500 | 6.5 | 2000 | 2.0 | 25000 | 25 |

From this example, you can see if you order 100 pieces of toy guitar, Aluminum molding will be cheaper than 3D printing, but steel molding is still higher than 3D printing. But if you order 1000 pieces, 3D printing becomes the most expensive option. We hope now you can make your decision.

Types of Plastic

The type of plastic also affects the final production cost. The plastic used in 3D printing is more expensive than those used in 3D printing. If you want to use Polycarbonate or Nylon, those are also expensive for 3D printing.

So in terms of materials, injection molding is more cost-effective.

The shape of your Product

The shape of your product also affects the final product price. If the design is too complicated, the initial cost of injection molding will cost more.

Manufacturing Method

There are several types of 3D printing. For example, if you choose the Stereolithography process, that will cost more than the traditional FDM process.

Conclusion

If you were looking for the answer to the question of “How to make injection molding more cost-effective,” we hope this article has provided you with the exact information. So, now you can choose the most cost-effective method that suits your requirements.