Carbon brushes are one of the most critical components of electric motors and generators but are often overlooked. They are crucial in other equipment where electrical current needs to be conducted through a rotating or moving component, such as power tools, electric vehicles, and audio equipment.

Over time, carbon brushes will wear down and need replacement. In some cases, they can be repaired and reused. So, it is best to know how to properly utilize, maintain and fix carbon brushes to prolong their lifespan and prevent expensive repairs or frequent replacements. That said, read this article to learn about carbon brushes, their use, and how to keep them in good working order.

What Is A Carbon Brush?

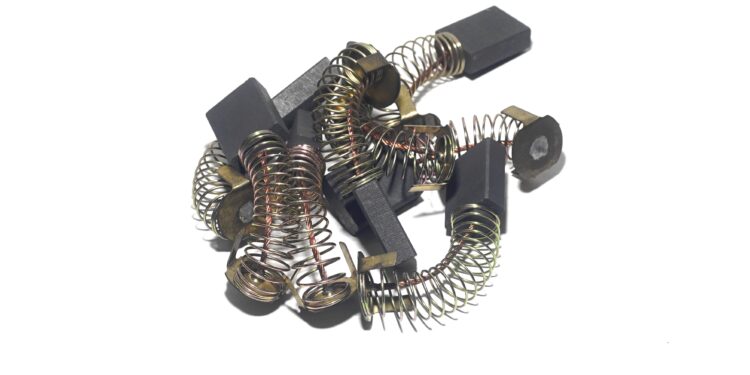

Carbon brushes are small, rectangular blocks of carbon that conduct electricity between a rotating or moving component and a stationary component. Carbon brushes are made from a carbon block with electrical connections on both ends. The rotating or moving part is typically an electric motor or generator, and the stationary component is a commutator or slip ring.

Carbon brushes are made of graphite, a form of carbon, and they conduct electricity by using the carbon atoms in the graphite to create a path for the current. The carbon brushes can conduct electricity because the graphite in the carbon brushes is in the form of a sheet that can conduct electricity by sliding over the surface of the metal.

Where To Purchase Carbon Brushes

Even with the best maintenance strategy, carbon brushes may wear out to the extent that you must replace them. There are many replacement services available. The trick is to hire experts for quality carbon brushes. Once you’ve decided on the size and type you need, you can purchase a new carbon brush from retailers like Replacement Carbon Brushes.

What Are Carbon Brushes Used For?

The primary role of carbon brushes is to transfer electrical current from the rotating part of the motor (the armature) to the stationary part (the stator). This current transfer creates a magnetic field that interacts with the armature to create torque, which turns the motor. The carbon brush also conducts the electricity from the armature to the commutator.

The commutator is a rotating switch that reverses the flow of electricity in the armature, causing the motor to rotate in the opposite direction. As the armature rotates, the brushes move along the surface of the commutator, making contact with the different segments.

Carbon brushes are also responsible for transferring heat away from the armature. It is essential because the armature can get very hot during operation, and this heat needs to be dissipated to avoid damage to the motor. As the electric current flows through the carbon brush, it will heat it. This heat is dissipated by the brush holder, which is usually made of metal. The brush holder helps keep the brush cool and holds it in place so it can make good contact with the commutator or slip ring.

While carbon brushes play a vital role in the operation of DC motors and generators, they are also used in various other electrical applications. For example, they are often used in power tools, such as drills and saws, to create an electrical connection between the moving and stationary parts of the tool. Carbon brushes are commonly used in starters and alternators to help transfer electrical current.

Aside from their conductivity, carbon brushes also offer some other benefits that make them ideal for their role in electrical applications. For instance, they can withstand high temperatures and are not susceptible to corrosion.

While carbon brushes offer many benefits, there are also a few drawbacks to using them in electrical applications. One of the biggest drawbacks is that carbon brushes can cause sparking, which can be a safety hazard. Additionally, carbon brushes wear out and will eventually need to be repaired or replaced.

How To Maintain Carbon Brushes

The proper maintenance of carbon brushes is critical to the longevity and performance of the equipment. You can do a few things to prolong the life of carbon brushes and minimize wear. You need to:

- Keep The Carbon Brushes Clean

First, the brushes should be kept clean and free of debris. The best way to clean carbon brushes is to use a soft cloth or brush. Never use a hard object to clean carbon brushes, as this can damage the carbon molecules and cause them to become less effective. If the brush is super dirty, it can be soaked in a mild detergent solution and then rinsed with clean water. In some cases, cleaning the commutator or slip ring may be necessary.

- Inspect The Carbon Brushes Regularly To Wear

In addition to keeping carbon brushes clean, it is also best to inspect them regularly for wear. Carbon brushes will eventually wear down and will need replacement. The amount of time that carbon brushes will last will depend on the application in which they are used.

The brushes should be replaced when they reach the end of their service life, typically indicated by a wear indicator on the brush itself. If your carbon brushes need replacing, it’s easy to do it yourself. The replacement process is simple. You can do it with a few basic tools.

- Keep Corrosion At Bay

Third, the contact area between the brush and the commutator should be corrosion-free. The contact area between the carbon brush and the commutator should be moisture-free to prevent corrosion. A light coating of silicone grease can also be applied to the contact area to help prevent corrosion.

- Use Carbon Brushes In The Right Way

To get carbon brushes to last longer, use them in applications where they will not be subject to excessive wear. For example, carbon brushes used in electric motors that are not constantly running will last longer than those used in constantly running electric motors.

Maintaining carbon brushes is essential to properly function electric motors, generators, and starters. By keeping carbon brushes well maintained, you can extend their life and ensure they continue working.

How To Repair Carbon Brushes

One issue with carbon brushes, as previously indicated, is that they wear out with time. As the armature of the motor rotates, the carbon brushes rotate too. As the carbon block wears down, the electrical contacts become less effective at transferring electricity. It can eventually lead to a loss of power in the motor. Worn carbon brushes can also create sparks, which can be dangerous in some applications.

Carbon brushes need inspection and replacement periodically to prevent this from happening. In some cases, carbon brushes are reusable. You can do this by resurfacing the carbon brush. When resurfacing a carbon brush, it is best to remove all the old carbon from it. It is done with a brush resurfacing machine or by hand. Once all the old carbon has been removed, new carbon can be applied to the brush. The new carbon can be either in the form of a block or a powder.

The frequency with which the brush holder and the brush need to be repaired and replaced depends on the type of motor and the amount of use it gets. You’ll save money by doing the job and get your machine running like new again.

Conclusion

Carbon brushes are a crucial component in electric motors and generators. Without them, these devices would not be able to function. They are also used in various other equipment where electrical current needs to be conducted through a rotating or moving component. Over time, carbon brushes will wear down. So, it is best to keep them in good condition by inspecting, repairing, or replacing them. It will help extend the motor’s life and ensure it operates at its best.